Our outstanding reputation often precedes us

For over 50 years Saturn Ceramic Coating has been providing unsurpassed wear resistant coatings to industry:

- PUMPS: Dupont, Nascote Industries, Michigan Sugar, Solae Remington

- SPINDLES: Timken, Torrington, Ford, Caterpillar, GE, Whirlpool

- BUFFING: ITW Industrial Finishing, Acme Manufacturing, Kohler Faucet

- INDUCTION/ FORGING: Inductoheat, Ajax Tocco, Tucker, Electroheat, Trenton Forging

Engineers and maintenance department heads specify Saturn Ceramic Coating Company on blueprints

to ensure quality and performance.

What other coating companies don't want you to know

Rod-form ceramic coatings are better

Rod-form ceramic coatings are better

Saturn Ceramic Coating specializes in applying rod-form ceramic- the hardest,

most wear-resistant coating.

ABRASIVE APPLICATIONS:

Greatly extends wear life of pump shafts, cylinders, wear sleeves, grinder spindles, seal surfaces,

forging skid rails and other rotational or reciprocating wear areas.

ELECTRICAL & THERMAL APPLICATIONS:

Protects expensive equipment by insulating induction coils, parts nests, welding locator pins,

heat shields and other components to provide an electrical or thermal barrier.

Our ceramic coatings last longer.. so your parts last longer

Our ceramic coatings last longer.. so your parts last longer

- Excellent rotational and reciprocating wear resistance along with unparalleled thermal protection & electrical non-conductivity.

- Saturn's rod-form ceramic application is the most difficult ceramic coating to apply and to finish.

- Saturn's rod-form process introduces a fused ceramic rod to a 5600-degree (F) flame. The 100% molten ceramic is blown onto the substrate at speeds up to 550 feet per second.

- Saturn's rod-form process delivers ceramic to the substrate with greater kinetic energy and thermal mass for higher particle-to-particle cohesive bonding.

- Heat transfer is 50% lower than with other application methods which avoids part warpage or distortion.

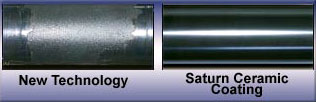

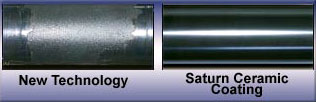

The "new" technology is not the answer

- Other companies have tried to spray rod-form ceramic and found it difficult or impossible to correctly

apply and accurately finish- this has been the catalyst for the so called "new" technology coatings.

- The "new" technology coatings are much easier to apply & finish. Attributes which benefit the

applicator, but result in an inferior coating.

- The maximum amount of these powdered-form ceramics that reaches the molten state is 80% and

could be as low as 20%. If it's not fully molten it won't bond properly either to the working particles or to the substrate.

- With powder-based coatings thermal nonconductivity, electrical insulation and wear resistance are all compromised.

- Parts can be distorted during application due to extreme heat.

What we also do for our customers

Ancillary Machining – Prep & Finish Work

Top quality machining prep work (turning, milling and welding) prior to coating and finishing parts to exacting tolerances.

- Roundness to within 20 millionths (.00002)

- Concentricity to within 50 millionths (.00005)

- Finish to a 9 micro RMS

- Straightness to within 50 millionths (.00005)

It is amazing what we can do with worn parts. Our remanufactured parts are often restored to better than original condition.

Manufacturing to Print – Complete Parts

Our parts meet all requirements as specified in your blueprints.

- Spindles

- Pump shafts

- Pump cylinders

- Locator pins

- Buffing fixtures

Rod-form ceramic coatings are better

Rod-form ceramic coatings are better  Our ceramic coatings last longer.. so your parts last longer

Our ceramic coatings last longer.. so your parts last longer